As an integrated manufacturer of power steering, the company has a complete product supply chain.

At present, the company has three core production workshops. In the intelligent transformation of high-end equipment and existing equipment, the company has invested a lot to ensure the continuous improvement of core manufacturing capacity. The annual production capacity of the company's power steering system has reached 1.5 million sets.

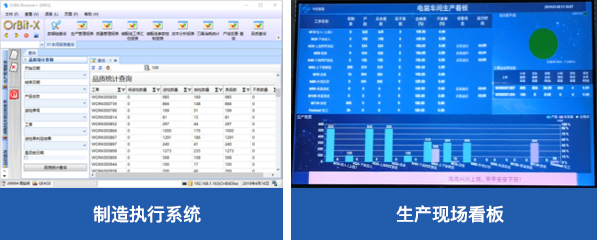

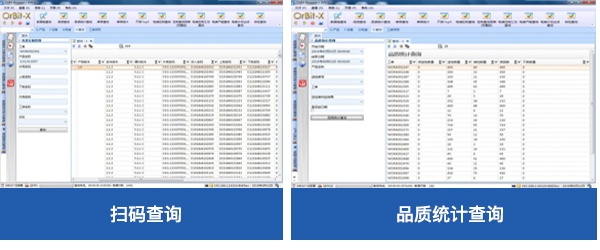

In the field of production and manufacturing information management, the company has invested a lot and has put on-line manufacturing execution system. It integrates production, quality, equipment, tooling and cutting tools into the system, realizes billboard and report management integrates with ERP, and gradually reaches the comprehensive retrospective management of parts and test data.

In terms of personnel assurance, the company has steadily strengthened training, improved the organizational structure, performance appraisal system and salary scheme, and stimulated employees' enthusiasm for work with performance-oriented. Under the multi-pronged incentive, the order delivery capability is effectively guaranteed.

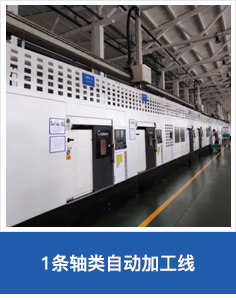

Machine workshop

It has six production lines to complete the processing of core mechanical parts.

Electrical Assembly Workshop

It has two production lines to complete the assembly and testing of core controller.

Mechanical Assembly Workshop

It has three assembly lines to complete assembly and testing of core components, five assembly lines to complete assembly and testing of power steering assembly, and one production line for steering gear.

Production and Manufacturing Information Management Display

CONTACT

Address:100, Hangkong RD. Dongjiaduan Hi-tech Industrial park, Lusong District, Zhuzhou, Hunan, China.

Mailbox: cs@nfelite.com

Phone:0731-28579269、28554901